designing

for recycling

National Trust of

Scottish Visitors' Centre

Glencoe, Scotland, UK

Client: National Trust

of Scottish

Architect: Gaia Architects

Landscape architect: Gaia Architects

Quantity Surveyor: Ralph Ogg & Partners

Main Contractor: R.J. McLeod

Completed: 2002

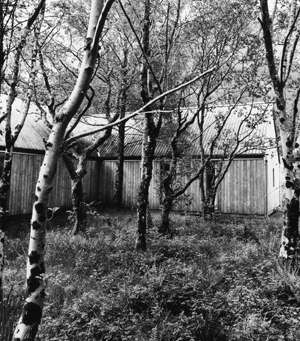

In 1994 Gaia Architects were commissioned by the National Trust of Scotland to design a new visitor centre for their site in Glencoe, the site of the massacre of the MacDonald clan. Following a consultation period with the local community and the Trust itself and a lengthy search for funding, the construction of the new centre started in 2000 and was completed in 2002.

The Trust wanted the

building to be 'green' and the brief was therefore developed by the architects

to cover sustainability issues regarding the site, resources, energy and

health.

Under the heading of 'resources' Gaia Architects considered the use of

materials and focused on the principle that the most effective way to

reduce the use of materials is to maximise the life of the building. This

aim was pursued by following the principle of building in layers, a concept

put forward by Steward Brand in his book 'How buildings learn'. Brand

promotes a layered construction where each layer is designed to be as

independent as possible providing both flexibility and the ability to

upgrade or modify the exposed layers.

The theory of building in layers was put into practice at Glencoe by designing the structural frame, the services and the finishes as distinct elements with minimal interconnections. A timber portal frame was chosen and designed to be structurally independent from internal partitions. This produced a flexible internal layout, where internal partitions could be repositioned without affecting the structural frame, thus facilitating future changes to the internal layout and use.

The frame is built as a breather wall construction with a waterproof layer externally fixed to a processed timber board, insulation between framing elements and a board internally and constitutes both the essential structural and weather-protecting layer of the building. The external cladding and the internal finishes are two layers independent from the main structural frame, which can be maintained, upgraded and altered without affecting the frame. To enable the various layers to be accessed all fixings are generally bolted or screwed and adhesives are avoided all together. This enables elements to be removed without damage. The dismantled elements can then be reused elsewhere or if reuse is impossible, allows them to be recycled.

Fixings are generally

left exposed to facilitate their access. Speed of disassembly not only

facilitates the dismantling of a building, it makes dismantling more economically

viable and facilitates maintenance reducing maintenance time and therefore

costs. Due to cost constraints the external timber cladding is nailed

rather screwed, this concession was made taking into account the requirement

for removing the cladding will mainly arise when the timber has deteriorated

and can at best be recycled, but not reused. The cladding is fixed with

only two nails per board, this allows the timber to move, but also reduces

the number of fixings and potential contaminants should the timber be

recycled.

The layering approach has also been used for the services. Between the

frame and the internal finishes are service voids located in the floors,

walls and ceiling housing the electrical wiring and heating pipes. The

voids are easily accessed through skirtings and a specially detailed flooring

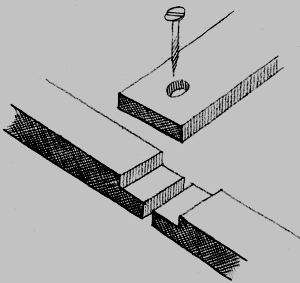

system, which again relies on exposed fixings. The flooring system, which

involved rebating each floor board and locating a fixing trim between

two rebated edges, already proved its worth during the fit-out contract

which involved repositioning services.

In order to maximise

the potential for recycling, materials were specified without coatings

and finishes where appropriate and composite materials were avoided. Timber

was used rather then chipboard and mill finished aluminium rather than

coated steel.

A few areas of the building remain traditionally inflexible and not dismantleable.

The rendered exterior finish and the tiling to the wet areas are traditional

single use finishes. But also the plasterboard internal finish, while

it is screwed with taped joints would prove difficult to disassemble and

the boards are notoriously impossible to reuse. Solutions to these culturally

sensitive finishes are still in their infancy. Perhaps, in this primarily

timber building, a timber boarding with exposed fixings as an internal

finish could have made this building virtually 100% recyclable.

BUILDING SUSTAINABLE DESIGN FEATURES

Site and Ecology

The existing building was demolished and recycled and the new building

located on the site of an old caravan park was designed to nestle in the

landscape. The original site was returned to natural use, an existing

culverted stream was reopened and native planting reintroduced.

Community and Culture

The design involved a community consultation. The materials used are mainly

local both in character and production, thus supporting the regional economy.

Health

The timber was not treated, avoiding preservative and relying on appropriate

detailing and the correct choice of durable timber for each purpose. Polyvinylchloride

(PVC) was not used and glues associated with volatile organic compounds

off gassing kept to a minimum.

Materials

The timber specified was a local grown Scottish timber.

Energy

The building structure has a U-value of approximately 0.14 W/m²K

and was detailed to be air tight. The heating is supplied by a woodchip

boiler making the development including the caravan site carbon neutral.

Water

Water is supplied to the building from a spring fed reservoir. The water

is not chlorinated but treated with silver copper ionisation. The sewage

system, which is linked to the camp site, was upgrade to return clean

water to the River Coe. Low flush toilets, aerating taps and other water

saving approaches were included.